Model Rocket Kit: Launch Yourself into Fun and Adventure

Building a model may be a challenging experience, but it’s very rewarding in the end. It teaches attention to detail and patience, and with most kits, the builders learn much about the object they’re reproducing, whether it’s a car, ship, aeroplane or rocket.

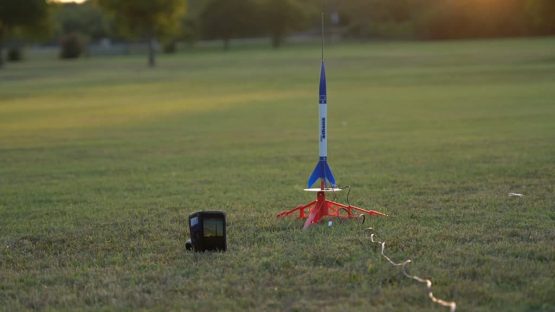

Model rocket kits are a relatively safe and inexpensive way for students to learn the basics of forces and the response of vehicles to external forces. Designing a model rocket kit can be completed in a few different ways. One of the first things you’ll need to decide is whether you’ll opt for modifying an existing rocket model or start from scratch by assembling individual parts and pieces.

Building Your Fully Operational Model Rocket

When it comes to modifying an existing rocket model, it includes changing the rocket’s exterior or the manufacturer’s performance specifications. Some of the options for modifying a rocket model are adding a stage, increasing engine size, or adding engines to create an engine cluster. On the other hand, when starting from scratch and assembling individual parts, you have complete control of what your rocket will look like.

Model rocketry requires the rocket and some accessories like wadding, fin straighteners, engines and batteries. You can choose your model rocket kit from a variety of rocket sets for any skill level, from beginner to advanced, from air-powered to engine-powered. The most important thing is to pay attention to the instructions so that you can get the best result.

Model Rocket Parts

To get a better understanding of how a model rocket works and to build and design your own, you need to know its anatomy first. A standard model rocket is made of the following basic components and there is a science behind the construction and materials used to make any of them, which can directly affect the performance of your model rocket.

Nose

The nose cone has a shape that causes the air to flow around the rocket. It is the leading factor in the aerodynamic ability of the rocket and plays a big role in detaching during the recovery operation, so the parachute can glide out and allow a safe trip back to the ground for your rocket. There are a few types of noses commonly used when designing a rocket kit and each one of them serves a different purpose based on its design and construction.

The most commonly used materials for nose cones are plastic, hardwood, balsa wood, fibreglass and styrofoam. The material chosen for model rocket noses is based on desired weight, strength and durability.

Body Tube

The body type is the main facet of the model rocket. It’s responsible for bringing all pieces together, including the nose, fin, engine and recovery system. The size of the body you choose always depends on the engine you’re going to use, the cone size and the weight you want to achieve.

Typically, the body of a rocket kit is made from spiral-wound paper tubing, plastic or fibreglass. When designing your model rocket, make sure you choose the material that is lightweight and durable, so it can fit your flying specifications.

Fins

These are essential in keeping the centre of pressure and centre of gravity in check on your rocket. The fins help the rocket to keep a stable and linear flight path and prevent environmental factors like the wind, aerodynamic forces and gravity to interact with the rocket during flights and take control over it. The recommended number of fins for a model rocket is three, however, it’s not unusual to purchase or design a rocket with more than three fins.

Model rocket fins are most commonly produced of wood, fibreglass or plastic. Choose the material that is ideal for the overall weight of your rocket and durability.

Engine Mount

Inside of the model rocket body, there is an engine mount that can be in the form of a kit that has an engine tube, engine hooks and centring rings. All of these stabilise the engine in the centre of the rocket body tube. Model rocket engines are available in many different sizes based on their classification.

However, keep in mind that a bigger engine doesn’t necessarily mean a better engine. A larger engine can pull more weight, but you can still see a small model rocket with a smaller engine achieving the same altitude as a large model rocket featuring a large engine.

Shock Cord

When your model rocket enters into the recovery stage, the nose is ejected from the top of it. The parachute will then deploy to safely bring the rocket to the ground, but to keep the nose and the body of the model rocket together during this process, a shock cord needs to be installed. It’s an elastic and fire-resistant rope that holds onto the body of the model rocket. You need to make sure the shock cord is properly fitted into what is referred to as a shock cord mount within the body, so it can maintain a hold onto the rocket’s nose and body after it’s been detached.

Parachute and Wadding

The model rocket parachute brings the rocket down to the ground safely and with little to no damage. You can determine the size of the parachute based on the weight of your rocket. Determining the size of the parachute is based on a few factors, such as the force of gravity, drag force, or wind resistance, and intended velocity descent.